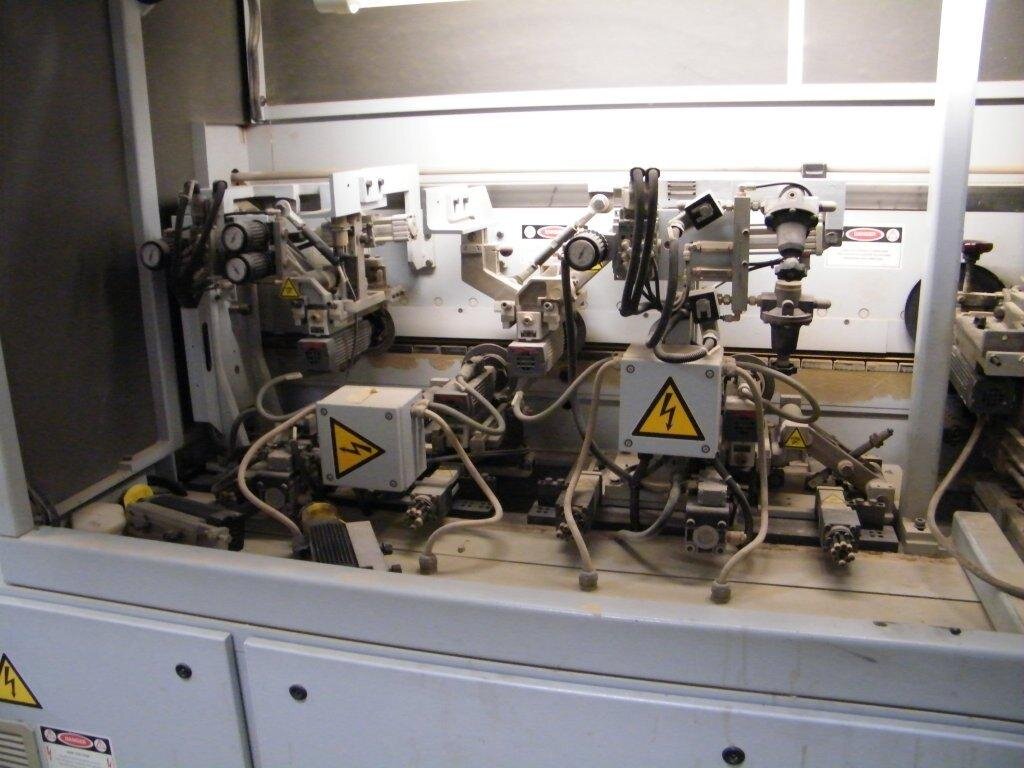

Brandt KDF 1870 Edgebander (Used)

This machine is UL approved as a complete unit.

PC-20 Program Control

- PC: Industrial PC, 600 Mhz, Front side USB port.

- Memory: 256 Mb ram, 1 Gb Flash Card.

- Screen: 12.1” Color, 800 x 600 pixel, Active TFT Screen.

- Internal modem for remote diagnostic link.

Motorized top pressure beam for panel thickness adjustment. Smooth upper pressure rollers and

internal lighting.

Automatic feed track lubrication system. Program controlled in feed fence positioning

Automatic magazine for coil feeding from outside the machine.

Work piece gap optimization reduces spacing between parts to increase output.

Joint trimming unit for pre-trimming the work piece edge prior to processing.

Quick melt granulate glue application system with twelve minute heat-up time. Quick-change glue

tank for easy maintenance and glue color change, if necessary.

Infrared radiant quartz heating unit between glue roller and pressure zone for optimum gluing

strength.

Program controlled positioning of the pressure zone. First pressure roller driven and three idle

pressure rollers.

Double motor end trimming unit with straight and chamfer capability. Chamfer up to 15. Program

controlled indexing from straight to bevel end trimming.

Top and bottom flush trimming unit. Includes straight insert cutters. Two position

vertical indexing for flush trimming or rough trimming. Servo motor program

control to edge thickness. This unit also tilts 0 – 25 degrees for bevel trimming HPL.

Fine trimming unit with DFC cutter head technology, servo motor control for side

copy positioning and to edge thickness for the unit. Auto tilt. Radius / straight DFC

cutters included. This unit provides superior dust flow control of the trimmed chips

and provides precise trimming due to location of the vertical copy rollers.

Multi Functional Contour trimming unit for continuous trimming and profile corner

trimming. Magnetic Linear drive system with soft touch feature.

Quick Change Scraping unit for rigid PVC edges. Program controlled indexing.

Finish scraping unit.

Oscillating Buffing unit with 2 motors, 0.18 kw each. 2 cloth buffing discs.

Isolation transformer with variable in feed voltage for balancing all three phases of

incoming power. This transformer will dampen line noise.

Technical Specifications

Edge band thickness 0.4 – 20 mm (0.016" - 3/4” )

Coil cutoff maximum 0.8 x 60 mm

3.0 x 45 mm (PVC)

3.0 x 33 mm ( Wood coils )

Edgeband height 12 - 65 mm (1/2" – 2 9/16 ")

Panel length min. 160 mm (6 3/8")

Panel width min. 70 mm (2 3/4")

Panel thickness - min.

- max.

8 mm (5/16")

60 mm (2 3/8")

Feed speed – variable 8 m/min (26 FPM) to 20 m/min

(65 FPM ); 16 m/min (52 FPM)

when edge thickness exceeds 3 mm.

14 m/min ( 46 FPM ) when corner

rounding.

Feed motor 2.2 kw (3 HP)

Joint trimming unit – two motors

Cutting speed

2.2 kw ( 3 HP each )

12,000 RPM

Pressure section First roller driven, 4 idle rollers

End trim unit - two motors

Cutting speed

Straight cut max.

.35 kw (1/2 HP ea)

12,000 RPM

20 x 45 mm (3/4" x 1 3/4")

Flush / Fine trimming unit

Cutter speed

Tilt range

1.85 kw ( 2.5 HP ) each

12,000 RPM

0 – 25 degrees

Fine trimming unit-auto tilt

Cutter speed

.55 kw (3/4 HP each)

12,000 RPM

Multi Function trimming unit - top

and bottom

0.4 kw (1/2 HP ea - two motors)

Total power required 35 kw

Amperage @ 230

@ 460

70 amps

35 amps

Machine length 6760 mm (22' 2”)

Machine width 1560 mm (61 ½ ")

Working height 950 mm (37 3/8")

Total height (hoods open) 2300 mm (7’ 6 ½”)

Machine net weight 3200 kg (7040 lbs.)

Electrical connection: 208/230 or 440/480 volt, 3-phase, 60 Hz.

Dust extraction:1x 120 mm (4 3/4"), 1x200 mm (8”), 1x 100 mm (4”), 3000 CFM.

Compressed air connection: 0.18 CFM per panel, 6 bars (85 PSI).

This machine is UL approved as a complete unit.

PC-20 Program Control

- PC: Industrial PC, 600 Mhz, Front side USB port.

- Memory: 256 Mb ram, 1 Gb Flash Card.

- Screen: 12.1” Color, 800 x 600 pixel, Active TFT Screen.

- Internal modem for remote diagnostic link.

Motorized top pressure beam for panel thickness adjustment. Smooth upper pressure rollers and

internal lighting.

Automatic feed track lubrication system. Program controlled in feed fence positioning

Automatic magazine for coil feeding from outside the machine.

Work piece gap optimization reduces spacing between parts to increase output.

Joint trimming unit for pre-trimming the work piece edge prior to processing.

Quick melt granulate glue application system with twelve minute heat-up time. Quick-change glue

tank for easy maintenance and glue color change, if necessary.

Infrared radiant quartz heating unit between glue roller and pressure zone for optimum gluing

strength.

Program controlled positioning of the pressure zone. First pressure roller driven and three idle

pressure rollers.

Double motor end trimming unit with straight and chamfer capability. Chamfer up to 15. Program

controlled indexing from straight to bevel end trimming.

Top and bottom flush trimming unit. Includes straight insert cutters. Two position

vertical indexing for flush trimming or rough trimming. Servo motor program

control to edge thickness. This unit also tilts 0 – 25 degrees for bevel trimming HPL.

Fine trimming unit with DFC cutter head technology, servo motor control for side

copy positioning and to edge thickness for the unit. Auto tilt. Radius / straight DFC

cutters included. This unit provides superior dust flow control of the trimmed chips

and provides precise trimming due to location of the vertical copy rollers.

Multi Functional Contour trimming unit for continuous trimming and profile corner

trimming. Magnetic Linear drive system with soft touch feature.

Quick Change Scraping unit for rigid PVC edges. Program controlled indexing.

Finish scraping unit.

Oscillating Buffing unit with 2 motors, 0.18 kw each. 2 cloth buffing discs.

Isolation transformer with variable in feed voltage for balancing all three phases of

incoming power. This transformer will dampen line noise.

Technical Specifications

Edge band thickness 0.4 – 20 mm (0.016" - 3/4” )

Coil cutoff maximum 0.8 x 60 mm

3.0 x 45 mm (PVC)

3.0 x 33 mm ( Wood coils )

Edgeband height 12 - 65 mm (1/2" – 2 9/16 ")

Panel length min. 160 mm (6 3/8")

Panel width min. 70 mm (2 3/4")

Panel thickness - min.

- max.

8 mm (5/16")

60 mm (2 3/8")

Feed speed – variable 8 m/min (26 FPM) to 20 m/min

(65 FPM ); 16 m/min (52 FPM)

when edge thickness exceeds 3 mm.

14 m/min ( 46 FPM ) when corner

rounding.

Feed motor 2.2 kw (3 HP)

Joint trimming unit – two motors

Cutting speed

2.2 kw ( 3 HP each )

12,000 RPM

Pressure section First roller driven, 4 idle rollers

End trim unit - two motors

Cutting speed

Straight cut max.

.35 kw (1/2 HP ea)

12,000 RPM

20 x 45 mm (3/4" x 1 3/4")

Flush / Fine trimming unit

Cutter speed

Tilt range

1.85 kw ( 2.5 HP ) each

12,000 RPM

0 – 25 degrees

Fine trimming unit-auto tilt

Cutter speed

.55 kw (3/4 HP each)

12,000 RPM

Multi Function trimming unit - top

and bottom

0.4 kw (1/2 HP ea - two motors)

Total power required 35 kw

Amperage @ 230

@ 460

70 amps

35 amps

Machine length 6760 mm (22' 2”)

Machine width 1560 mm (61 ½ ")

Working height 950 mm (37 3/8")

Total height (hoods open) 2300 mm (7’ 6 ½”)

Machine net weight 3200 kg (7040 lbs.)

Electrical connection: 208/230 or 440/480 volt, 3-phase, 60 Hz.

Dust extraction:1x 120 mm (4 3/4"), 1x200 mm (8”), 1x 100 mm (4”), 3000 CFM.

Compressed air connection: 0.18 CFM per panel, 6 bars (85 PSI).

This machine is UL approved as a complete unit.

PC-20 Program Control

- PC: Industrial PC, 600 Mhz, Front side USB port.

- Memory: 256 Mb ram, 1 Gb Flash Card.

- Screen: 12.1” Color, 800 x 600 pixel, Active TFT Screen.

- Internal modem for remote diagnostic link.

Motorized top pressure beam for panel thickness adjustment. Smooth upper pressure rollers and

internal lighting.

Automatic feed track lubrication system. Program controlled in feed fence positioning

Automatic magazine for coil feeding from outside the machine.

Work piece gap optimization reduces spacing between parts to increase output.

Joint trimming unit for pre-trimming the work piece edge prior to processing.

Quick melt granulate glue application system with twelve minute heat-up time. Quick-change glue

tank for easy maintenance and glue color change, if necessary.

Infrared radiant quartz heating unit between glue roller and pressure zone for optimum gluing

strength.

Program controlled positioning of the pressure zone. First pressure roller driven and three idle

pressure rollers.

Double motor end trimming unit with straight and chamfer capability. Chamfer up to 15. Program

controlled indexing from straight to bevel end trimming.

Top and bottom flush trimming unit. Includes straight insert cutters. Two position

vertical indexing for flush trimming or rough trimming. Servo motor program

control to edge thickness. This unit also tilts 0 – 25 degrees for bevel trimming HPL.

Fine trimming unit with DFC cutter head technology, servo motor control for side

copy positioning and to edge thickness for the unit. Auto tilt. Radius / straight DFC

cutters included. This unit provides superior dust flow control of the trimmed chips

and provides precise trimming due to location of the vertical copy rollers.

Multi Functional Contour trimming unit for continuous trimming and profile corner

trimming. Magnetic Linear drive system with soft touch feature.

Quick Change Scraping unit for rigid PVC edges. Program controlled indexing.

Finish scraping unit.

Oscillating Buffing unit with 2 motors, 0.18 kw each. 2 cloth buffing discs.

Isolation transformer with variable in feed voltage for balancing all three phases of

incoming power. This transformer will dampen line noise.

Technical Specifications

Edge band thickness 0.4 – 20 mm (0.016" - 3/4” )

Coil cutoff maximum 0.8 x 60 mm

3.0 x 45 mm (PVC)

3.0 x 33 mm ( Wood coils )

Edgeband height 12 - 65 mm (1/2" – 2 9/16 ")

Panel length min. 160 mm (6 3/8")

Panel width min. 70 mm (2 3/4")

Panel thickness - min.

- max.

8 mm (5/16")

60 mm (2 3/8")

Feed speed – variable 8 m/min (26 FPM) to 20 m/min

(65 FPM ); 16 m/min (52 FPM)

when edge thickness exceeds 3 mm.

14 m/min ( 46 FPM ) when corner

rounding.

Feed motor 2.2 kw (3 HP)

Joint trimming unit – two motors

Cutting speed

2.2 kw ( 3 HP each )

12,000 RPM

Pressure section First roller driven, 4 idle rollers

End trim unit - two motors

Cutting speed

Straight cut max.

.35 kw (1/2 HP ea)

12,000 RPM

20 x 45 mm (3/4" x 1 3/4")

Flush / Fine trimming unit

Cutter speed

Tilt range

1.85 kw ( 2.5 HP ) each

12,000 RPM

0 – 25 degrees

Fine trimming unit-auto tilt

Cutter speed

.55 kw (3/4 HP each)

12,000 RPM

Multi Function trimming unit - top

and bottom

0.4 kw (1/2 HP ea - two motors)

Total power required 35 kw

Amperage @ 230

@ 460

70 amps

35 amps

Machine length 6760 mm (22' 2”)

Machine width 1560 mm (61 ½ ")

Working height 950 mm (37 3/8")

Total height (hoods open) 2300 mm (7’ 6 ½”)

Machine net weight 3200 kg (7040 lbs.)

Electrical connection: 208/230 or 440/480 volt, 3-phase, 60 Hz.

Dust extraction:1x 120 mm (4 3/4"), 1x200 mm (8”), 1x 100 mm (4”), 3000 CFM.

Compressed air connection: 0.18 CFM per panel, 6 bars (85 PSI).