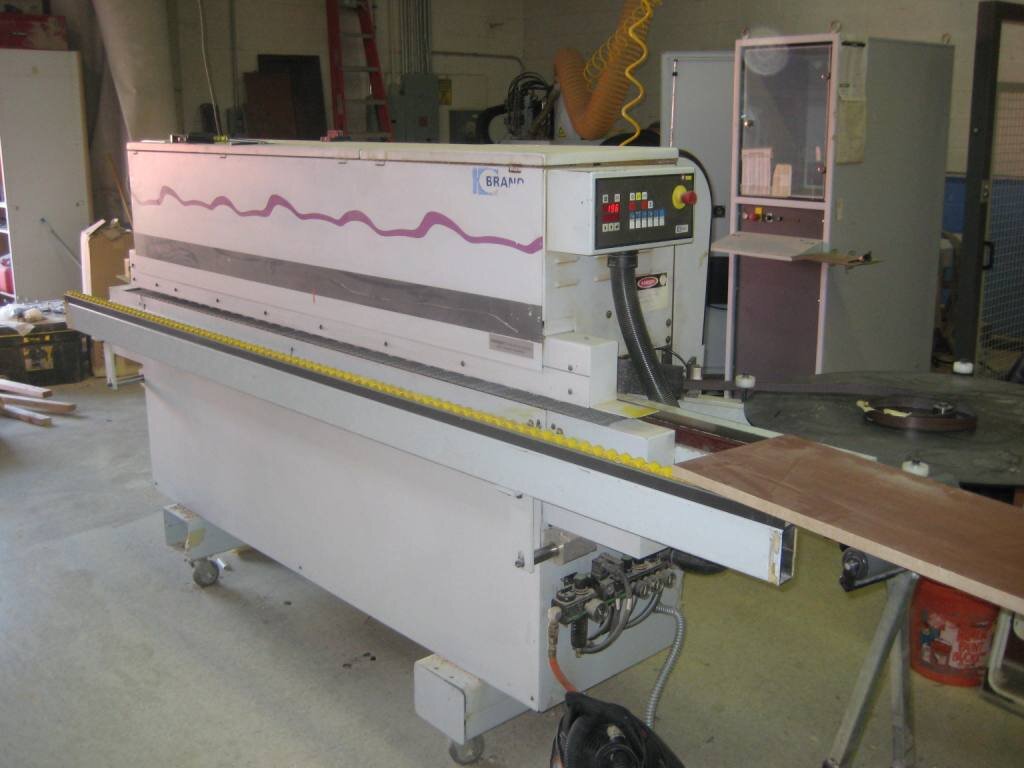

Holz-Her 1329 Edgebander 2019(Used)

VIDEO OF 1329 IN ACTION

HOLZ-HER 1329 SPRINT PREMIUM EDGEBANDER (W/PRE-MILL & CORNER ROUNDING) &

Features the HOLZ-HER Patented Dual "GLU-JET" EVA & PUR Zero Joint Technology System;

Specifications:

• Edgebanding Capacity: edge thickness min./max. 0.4 - 15 mm (0.016 - 1/2"), coiled material 0.4 - 3 mm

(0.016 - 0.157"); Panel thickness 8 - 60 mm (0.236 - 2.362"), workpiece width min. of 60 mm (2.36");

workpiece length min. 160 mm (6.29"); Feed speed 10 - 18 MPM (33 - 59 FPM).

• Programmable Logic Control (PLC) for Pre-Milling, edge feed, glue application, end trimming, flush

trimming, radius trimming, scraping, corner rounding, and buffing.

• Holz-Her PPC 315 "EDGE CONTROL TOUCH" Electronically controlled set-up processes with 100%

repetition accuracy.

18.5" Flat Touch Screen with Brilliant graphic display of machining process. Simple operation – rotating and

swiveling control panel at eye height.,

Programs can be easily created and recalled at will; Graphic interface makes programming easy,

Icon of each unit may be brought up on the screen to show the operator the status of the unit and the

parameters which can be programmed;

Edgebander can be operated manually when required, without necessity to write a program.

Machine In-Feed Configuration:

• Pre-Milling Station : (2) 2.0 KW (2.68 HP) - 12,000 RPM motors; Equipped with "ProLock" quick-change

flange including height adjustment for optimum utilization of cutters.

• Edge Feeder Magazine: "SYNCRO" drive. The new magazine with its synchronous adaptation to the feed

rate guarantees short intervals between work pieces & simultaneously optimizes edging protrusions. Small

3° feed angle thanks to nozzle design with easy feeding of coils, strips &up to 3 mm & solid wood edging up

to 15 mm (.059"). Exclusive "Tractor-Belt feed System", edge guide equipped with automatic guillotine lockout

for safety,

• Pressure Section: Servo controlled pressure section with (1) large driven roller and (2) cantered idle

rollers. Straight and tapered pressure rollers for perfect glued joints

• GLUING SYSTEM: "GUL Jet" thin film technology processes "EVA" or "PUR" Glue in Cartridge of

Granulate Form, motorized, programmable glue nozzle (upper glue line) height positioning.

Workstations:

• End Trimming Unit (1918-P): Front & rear 2 x 0.35 KW (0.5 HP) - 9,000 RPM motor each, uni-point

swivel-axis for no re-indexing when changing from flush to bevel end trim (0° - 10° bevel),"PCS"

programmable pneumatic change-over from flush to bevel.

• Multi-function Trimming Unit (1827 MOT4): Servo controlled, 2 @ servo motors (1) for horizontal copy

wheel & (1) for tool spindle position) programmable top & bottom unit 2 x 0.65 KW (0.87 HP) - 12,000 RPM

each motor. Uni-Point design with no second adjustment, pneumatic, programmable tilt action for changing

the degree of bevel, digital counters for vertical copy wheel position and pneumatic air cylinder for in/out

pre-positioning of trimming motor.

3 spray unit to repel glue for PUR glue and high gloss finishes

VIDEO OF 1329 IN ACTION

HOLZ-HER 1329 SPRINT PREMIUM EDGEBANDER (W/PRE-MILL & CORNER ROUNDING) &

Features the HOLZ-HER Patented Dual "GLU-JET" EVA & PUR Zero Joint Technology System;

Specifications:

• Edgebanding Capacity: edge thickness min./max. 0.4 - 15 mm (0.016 - 1/2"), coiled material 0.4 - 3 mm

(0.016 - 0.157"); Panel thickness 8 - 60 mm (0.236 - 2.362"), workpiece width min. of 60 mm (2.36");

workpiece length min. 160 mm (6.29"); Feed speed 10 - 18 MPM (33 - 59 FPM).

• Programmable Logic Control (PLC) for Pre-Milling, edge feed, glue application, end trimming, flush

trimming, radius trimming, scraping, corner rounding, and buffing.

• Holz-Her PPC 315 "EDGE CONTROL TOUCH" Electronically controlled set-up processes with 100%

repetition accuracy.

18.5" Flat Touch Screen with Brilliant graphic display of machining process. Simple operation – rotating and

swiveling control panel at eye height.,

Programs can be easily created and recalled at will; Graphic interface makes programming easy,

Icon of each unit may be brought up on the screen to show the operator the status of the unit and the

parameters which can be programmed;

Edgebander can be operated manually when required, without necessity to write a program.

Machine In-Feed Configuration:

• Pre-Milling Station : (2) 2.0 KW (2.68 HP) - 12,000 RPM motors; Equipped with "ProLock" quick-change

flange including height adjustment for optimum utilization of cutters.

• Edge Feeder Magazine: "SYNCRO" drive. The new magazine with its synchronous adaptation to the feed

rate guarantees short intervals between work pieces & simultaneously optimizes edging protrusions. Small

3° feed angle thanks to nozzle design with easy feeding of coils, strips &up to 3 mm & solid wood edging up

to 15 mm (.059"). Exclusive "Tractor-Belt feed System", edge guide equipped with automatic guillotine lockout

for safety,

• Pressure Section: Servo controlled pressure section with (1) large driven roller and (2) cantered idle

rollers. Straight and tapered pressure rollers for perfect glued joints

• GLUING SYSTEM: "GUL Jet" thin film technology processes "EVA" or "PUR" Glue in Cartridge of

Granulate Form, motorized, programmable glue nozzle (upper glue line) height positioning.

Workstations:

• End Trimming Unit (1918-P): Front & rear 2 x 0.35 KW (0.5 HP) - 9,000 RPM motor each, uni-point

swivel-axis for no re-indexing when changing from flush to bevel end trim (0° - 10° bevel),"PCS"

programmable pneumatic change-over from flush to bevel.

• Multi-function Trimming Unit (1827 MOT4): Servo controlled, 2 @ servo motors (1) for horizontal copy

wheel & (1) for tool spindle position) programmable top & bottom unit 2 x 0.65 KW (0.87 HP) - 12,000 RPM

each motor. Uni-Point design with no second adjustment, pneumatic, programmable tilt action for changing

the degree of bevel, digital counters for vertical copy wheel position and pneumatic air cylinder for in/out

pre-positioning of trimming motor.

3 spray unit to repel glue for PUR glue and high gloss finishes

VIDEO OF 1329 IN ACTION

HOLZ-HER 1329 SPRINT PREMIUM EDGEBANDER (W/PRE-MILL & CORNER ROUNDING) &

Features the HOLZ-HER Patented Dual "GLU-JET" EVA & PUR Zero Joint Technology System;

Specifications:

• Edgebanding Capacity: edge thickness min./max. 0.4 - 15 mm (0.016 - 1/2"), coiled material 0.4 - 3 mm

(0.016 - 0.157"); Panel thickness 8 - 60 mm (0.236 - 2.362"), workpiece width min. of 60 mm (2.36");

workpiece length min. 160 mm (6.29"); Feed speed 10 - 18 MPM (33 - 59 FPM).

• Programmable Logic Control (PLC) for Pre-Milling, edge feed, glue application, end trimming, flush

trimming, radius trimming, scraping, corner rounding, and buffing.

• Holz-Her PPC 315 "EDGE CONTROL TOUCH" Electronically controlled set-up processes with 100%

repetition accuracy.

18.5" Flat Touch Screen with Brilliant graphic display of machining process. Simple operation – rotating and

swiveling control panel at eye height.,

Programs can be easily created and recalled at will; Graphic interface makes programming easy,

Icon of each unit may be brought up on the screen to show the operator the status of the unit and the

parameters which can be programmed;

Edgebander can be operated manually when required, without necessity to write a program.

Machine In-Feed Configuration:

• Pre-Milling Station : (2) 2.0 KW (2.68 HP) - 12,000 RPM motors; Equipped with "ProLock" quick-change

flange including height adjustment for optimum utilization of cutters.

• Edge Feeder Magazine: "SYNCRO" drive. The new magazine with its synchronous adaptation to the feed

rate guarantees short intervals between work pieces & simultaneously optimizes edging protrusions. Small

3° feed angle thanks to nozzle design with easy feeding of coils, strips &up to 3 mm & solid wood edging up

to 15 mm (.059"). Exclusive "Tractor-Belt feed System", edge guide equipped with automatic guillotine lockout

for safety,

• Pressure Section: Servo controlled pressure section with (1) large driven roller and (2) cantered idle

rollers. Straight and tapered pressure rollers for perfect glued joints

• GLUING SYSTEM: "GUL Jet" thin film technology processes "EVA" or "PUR" Glue in Cartridge of

Granulate Form, motorized, programmable glue nozzle (upper glue line) height positioning.

Workstations:

• End Trimming Unit (1918-P): Front & rear 2 x 0.35 KW (0.5 HP) - 9,000 RPM motor each, uni-point

swivel-axis for no re-indexing when changing from flush to bevel end trim (0° - 10° bevel),"PCS"

programmable pneumatic change-over from flush to bevel.

• Multi-function Trimming Unit (1827 MOT4): Servo controlled, 2 @ servo motors (1) for horizontal copy

wheel & (1) for tool spindle position) programmable top & bottom unit 2 x 0.65 KW (0.87 HP) - 12,000 RPM

each motor. Uni-Point design with no second adjustment, pneumatic, programmable tilt action for changing

the degree of bevel, digital counters for vertical copy wheel position and pneumatic air cylinder for in/out

pre-positioning of trimming motor.

3 spray unit to repel glue for PUR glue and high gloss finishes