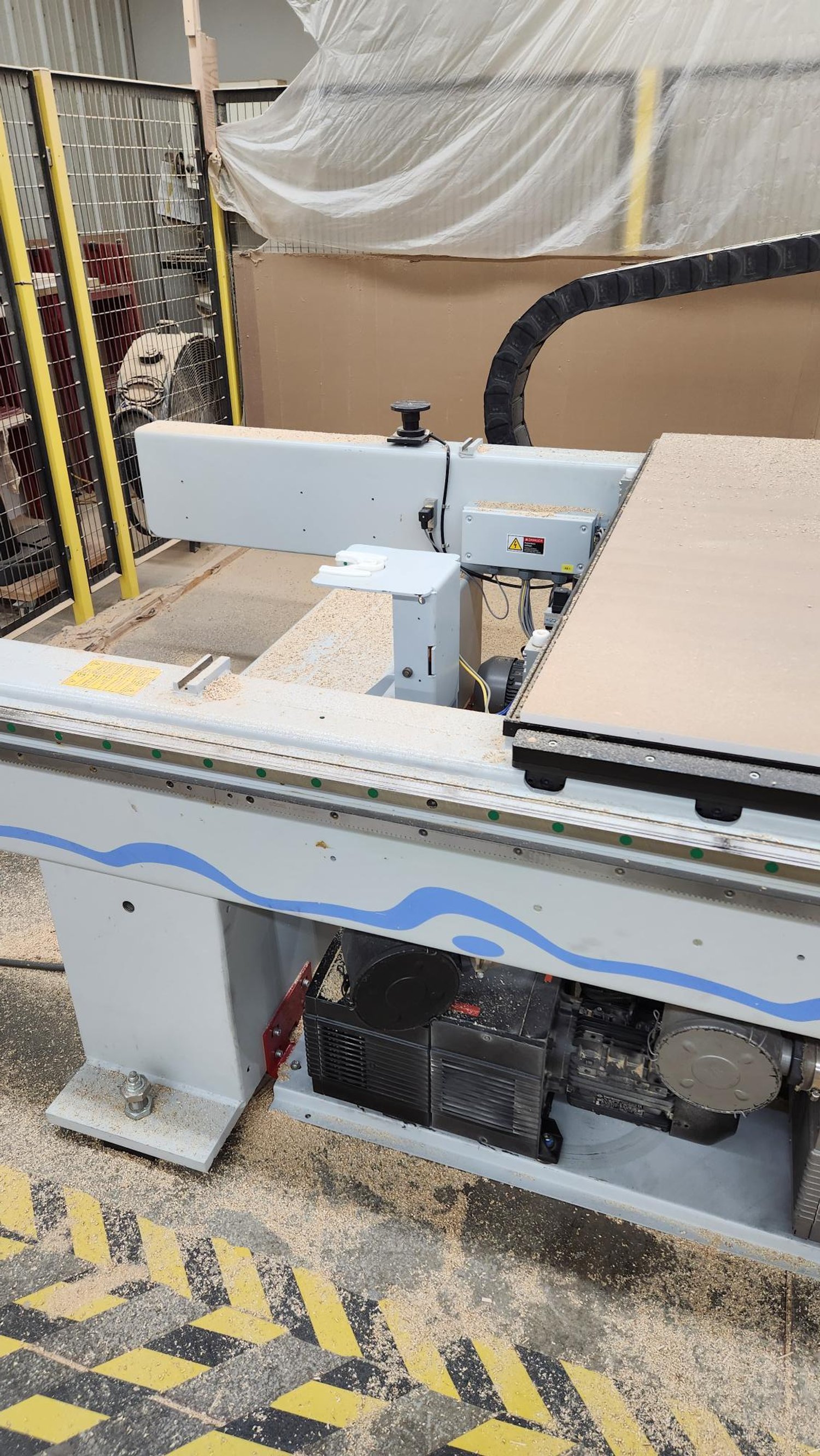

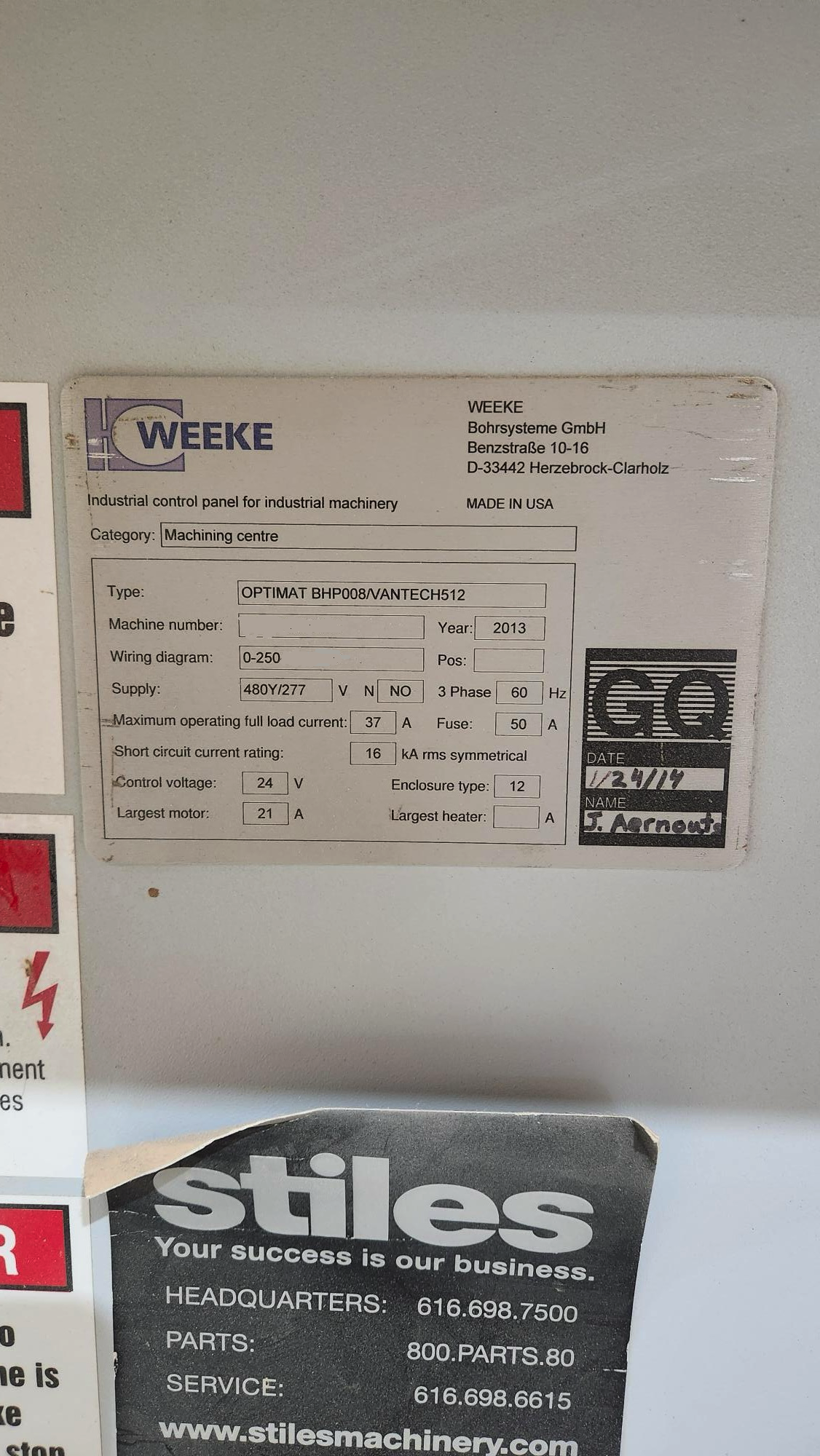

Weeke Vantech 5x12 Year 2013 - Sold new 2014 (Used)

2013 Weeke Vantech 5x12 with push off

First powered up 2014

Machine is currently under power

Service Log-book available

5' x 12' Flat Table "Bridge Gantry" machine with User-Friendly "S/C Tech" "MATRIX" grooved phenolic vacuum table.

"X" Axis is 145" (3,683 mm), "Y" axis 61" (1,550 mm), "Z" axis stroke is 9.6" (243.8 mm), max. material thickness of 3.9" (99 mm).

"X" Axis is 236 FPM (72 MPM), "Y" axis is 203 FPM (62 MPM), "Z" axis 82 FPM (25 MPM);

The head travels via AC brushless drives & THK linear motion guides on all axes.

S/C Tech MATRIX grooved phenolic vacuum table for easy vacuum pod placement; pneumatic locator/positioning pins.

(1) 12 Kw (16 HP) High speed electro-spindle router with "HSK F 63" adaptor; constant duty, variable speed from 1,250 - 24,000 RPM, RH or LH rotation.

(1) 12-Position Rotary ATC located at the end of machine.

Boring unit with 3.6 HP (2.7 kW) motor, (12) Independent vertical spindles with "Quick Change" drill bit holders; programmable variable speed from 1,500 - 7,500 RPM.

17" TFT Color graphic monitor, keyboard for data entry, PC 85T hand control pendant; CD R/W & floppy drives, EtherNET interface for LAN connection to office PC, RS-232 serial interface, USB ports.

(4) Vacuum pods for load/unload, 52" roller top on infeed side of machine.

61-1/2" x 162" Powered out-feed belt, top & bottom dust extraction.

2013 Weeke Vantech 5x12 with push off

First powered up 2014

Machine is currently under power

Service Log-book available

5' x 12' Flat Table "Bridge Gantry" machine with User-Friendly "S/C Tech" "MATRIX" grooved phenolic vacuum table.

"X" Axis is 145" (3,683 mm), "Y" axis 61" (1,550 mm), "Z" axis stroke is 9.6" (243.8 mm), max. material thickness of 3.9" (99 mm).

"X" Axis is 236 FPM (72 MPM), "Y" axis is 203 FPM (62 MPM), "Z" axis 82 FPM (25 MPM);

The head travels via AC brushless drives & THK linear motion guides on all axes.

S/C Tech MATRIX grooved phenolic vacuum table for easy vacuum pod placement; pneumatic locator/positioning pins.

(1) 12 Kw (16 HP) High speed electro-spindle router with "HSK F 63" adaptor; constant duty, variable speed from 1,250 - 24,000 RPM, RH or LH rotation.

(1) 12-Position Rotary ATC located at the end of machine.

Boring unit with 3.6 HP (2.7 kW) motor, (12) Independent vertical spindles with "Quick Change" drill bit holders; programmable variable speed from 1,500 - 7,500 RPM.

17" TFT Color graphic monitor, keyboard for data entry, PC 85T hand control pendant; CD R/W & floppy drives, EtherNET interface for LAN connection to office PC, RS-232 serial interface, USB ports.

(4) Vacuum pods for load/unload, 52" roller top on infeed side of machine.

61-1/2" x 162" Powered out-feed belt, top & bottom dust extraction.

2013 Weeke Vantech 5x12 with push off

First powered up 2014

Machine is currently under power

Service Log-book available

5' x 12' Flat Table "Bridge Gantry" machine with User-Friendly "S/C Tech" "MATRIX" grooved phenolic vacuum table.

"X" Axis is 145" (3,683 mm), "Y" axis 61" (1,550 mm), "Z" axis stroke is 9.6" (243.8 mm), max. material thickness of 3.9" (99 mm).

"X" Axis is 236 FPM (72 MPM), "Y" axis is 203 FPM (62 MPM), "Z" axis 82 FPM (25 MPM);

The head travels via AC brushless drives & THK linear motion guides on all axes.

S/C Tech MATRIX grooved phenolic vacuum table for easy vacuum pod placement; pneumatic locator/positioning pins.

(1) 12 Kw (16 HP) High speed electro-spindle router with "HSK F 63" adaptor; constant duty, variable speed from 1,250 - 24,000 RPM, RH or LH rotation.

(1) 12-Position Rotary ATC located at the end of machine.

Boring unit with 3.6 HP (2.7 kW) motor, (12) Independent vertical spindles with "Quick Change" drill bit holders; programmable variable speed from 1,500 - 7,500 RPM.

17" TFT Color graphic monitor, keyboard for data entry, PC 85T hand control pendant; CD R/W & floppy drives, EtherNET interface for LAN connection to office PC, RS-232 serial interface, USB ports.

(4) Vacuum pods for load/unload, 52" roller top on infeed side of machine.

61-1/2" x 162" Powered out-feed belt, top & bottom dust extraction.

5' x 12 Flat Table "Bridge Gantry" machine with User-Friendly "S/C Tech" "MATRIX" grooved phenolic vacuum table.

"X" Axis is 145" (3,683 mm), "Y" axis 61" (1,550 mm), "Z" axis stroke is 9.6" (243.8 mm), max. material thickness of 3.9" (99 mm).

"X" Axis is 236 FPM (72 MPM), "Y" axis is 203 FPM (62 MPM), "Z" axis 82 FPM (25 MPM);

The head travels via AC brushless drives & THK linear motion guides on all axes.

S/C Tech MATRIX grooved phenolic vacuum table for easy vacuum pod placement; pneumatic locator/positioning pins.

(1) 12 HP (9 kW) High speed electro-spindle router with "HSK F 63" adaptor; constant duty, variable speed from 1,250 - 24,000 RPM, RH or LH rotation.

PC Front-End with WEEKE "PC 85T" + Windows "XP" + WoodWOP 5.0 operating system.

14” (355.6mm) Post Rotary Tool Changer

17" TFT Color graphic monitor, keyboard for data entry, PC 85T hand control pendant; CD R/W & floppy drives, EtherNET interface for LAN connection to office PC, RS-232 serial interface, USB ports.

"BECKHOFF" Programmable logic control for (3/4) axes, linear, circular & helical interpolation; the controller is contained in a separate free-standing, dust-free control cabinet that can be placed at either the LH or RH side of the machine.

(4) Vacuum pumps; light curtain (machine will stop if operator enters work area), safety fencing, separate control cabinet.

Boring unit with 3.6 HP (2.7 kW) motor, (7) Independent vertical spindles with "Quick Change" drill bit holders; programmable variable speed from 1,500 - 7,500 RPM.

c/w Auto Feed table & Safety Gates