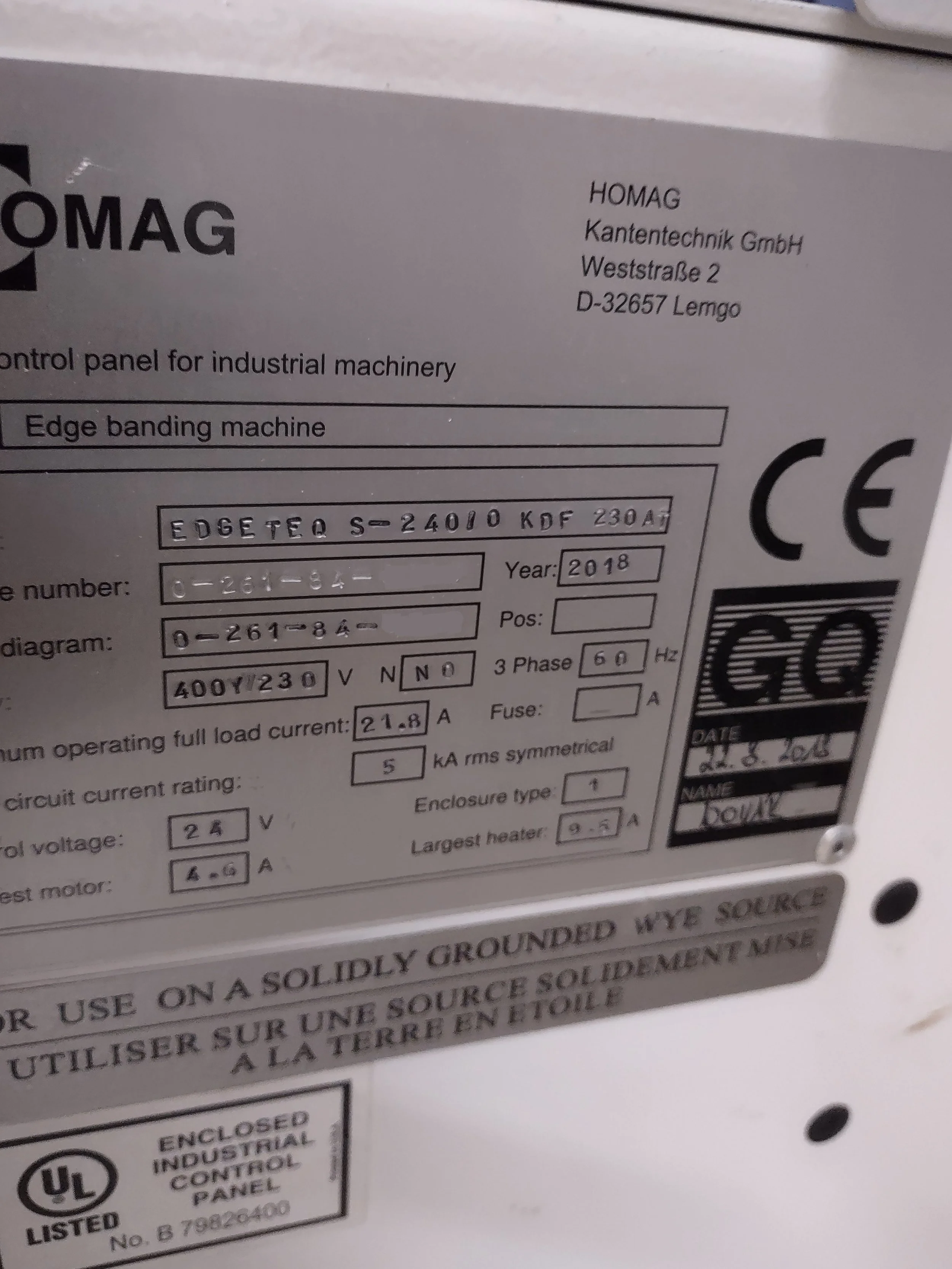

Homag 1230 Edgebander w/Airtec, Premill & Corner Rounding, 2018 (Used)

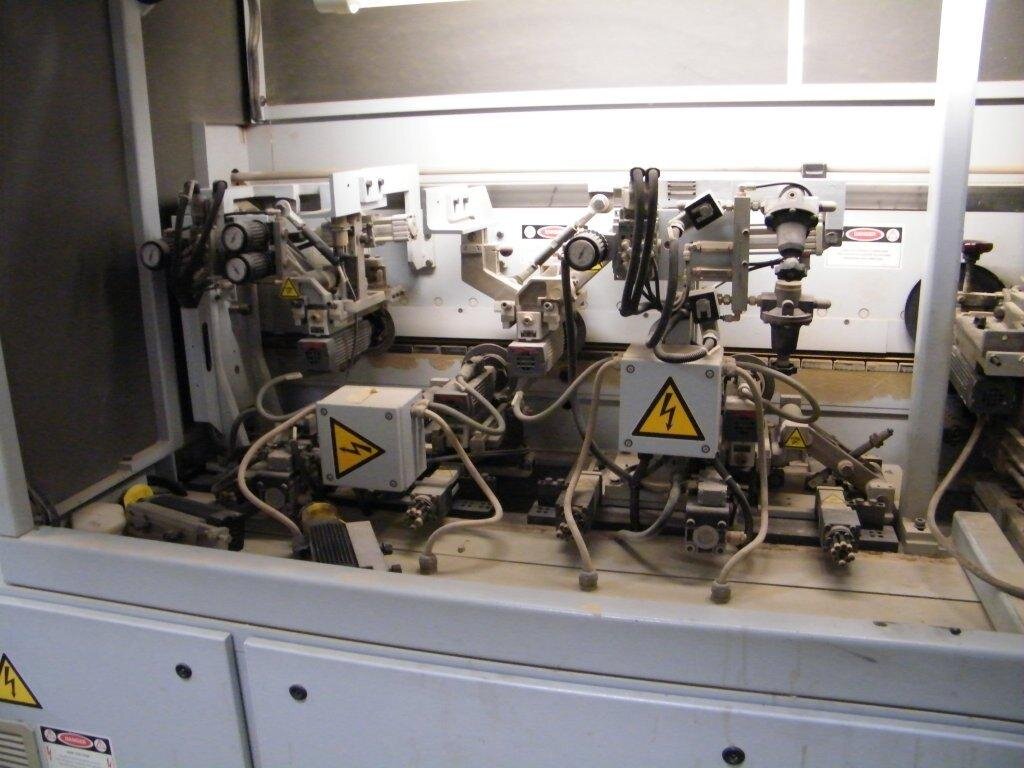

Machine Features:

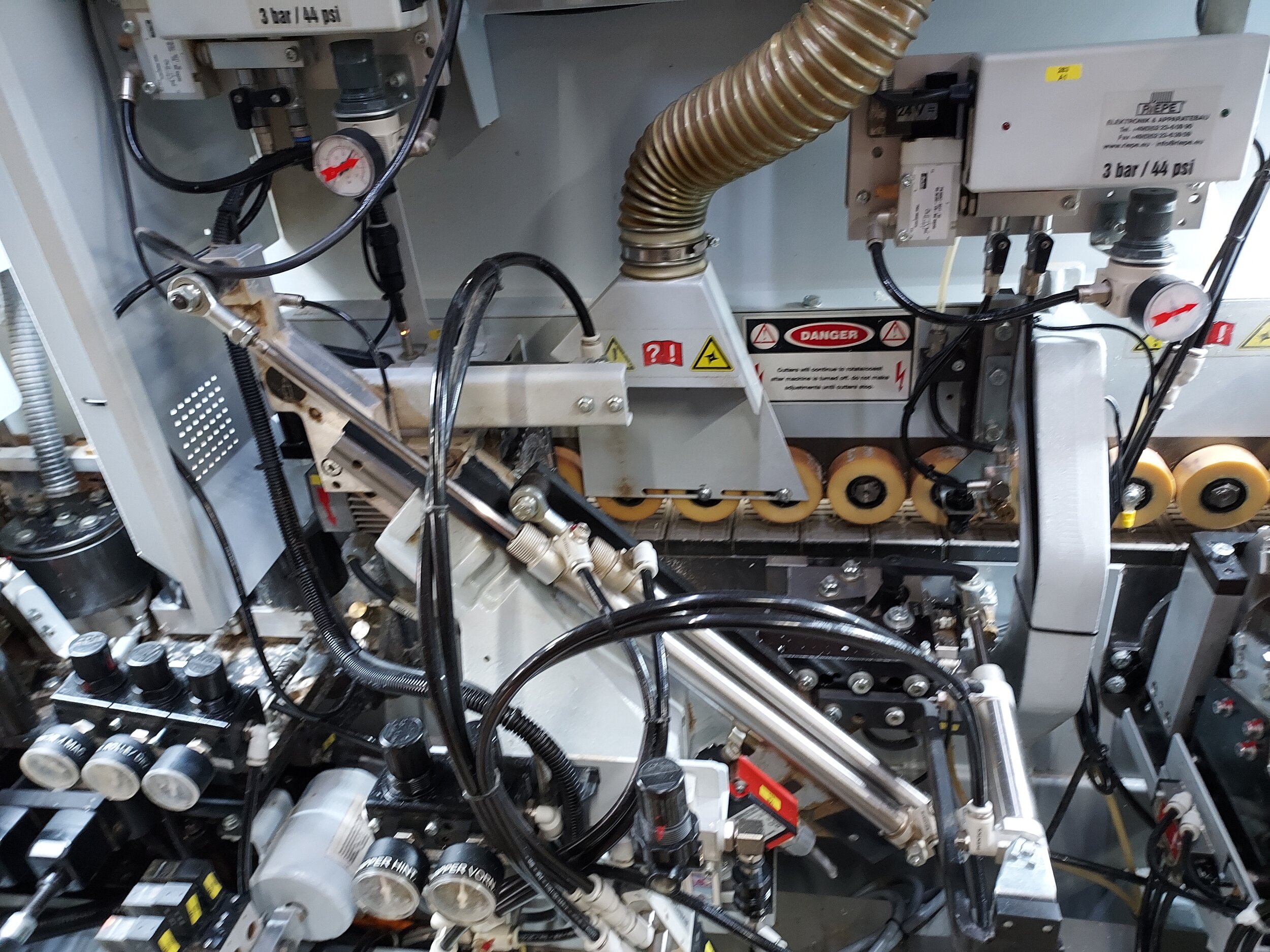

· integrated electronic line control system for increased reliability and diagnostic assistance – no limit switches used for setting operating units

· automatic magazine for strip and coil

· large coil table (800 mm diameter) to accommodate large coils of 3 mm PVC

· feed speed: 8 m/min

· workpiece thickness: 60 mm

· workpiece pre-heating (radiant style) for achieving optimal bond quality

· Joint Trimming Unit for pre-trimming the workpiece edge prior to processing

· QA-65 N glue application system with quick purge system

· automatic temperature reduction feature lowers the glue temperature if no workpiece is run over a 15-minute span (reheating accomplished in three minutes).

· AT 10 airTec Reactivation Unit for use with laser edgebanding to provide zero glue line results. Maximum workpiece thickness is 40 mm when using airTec

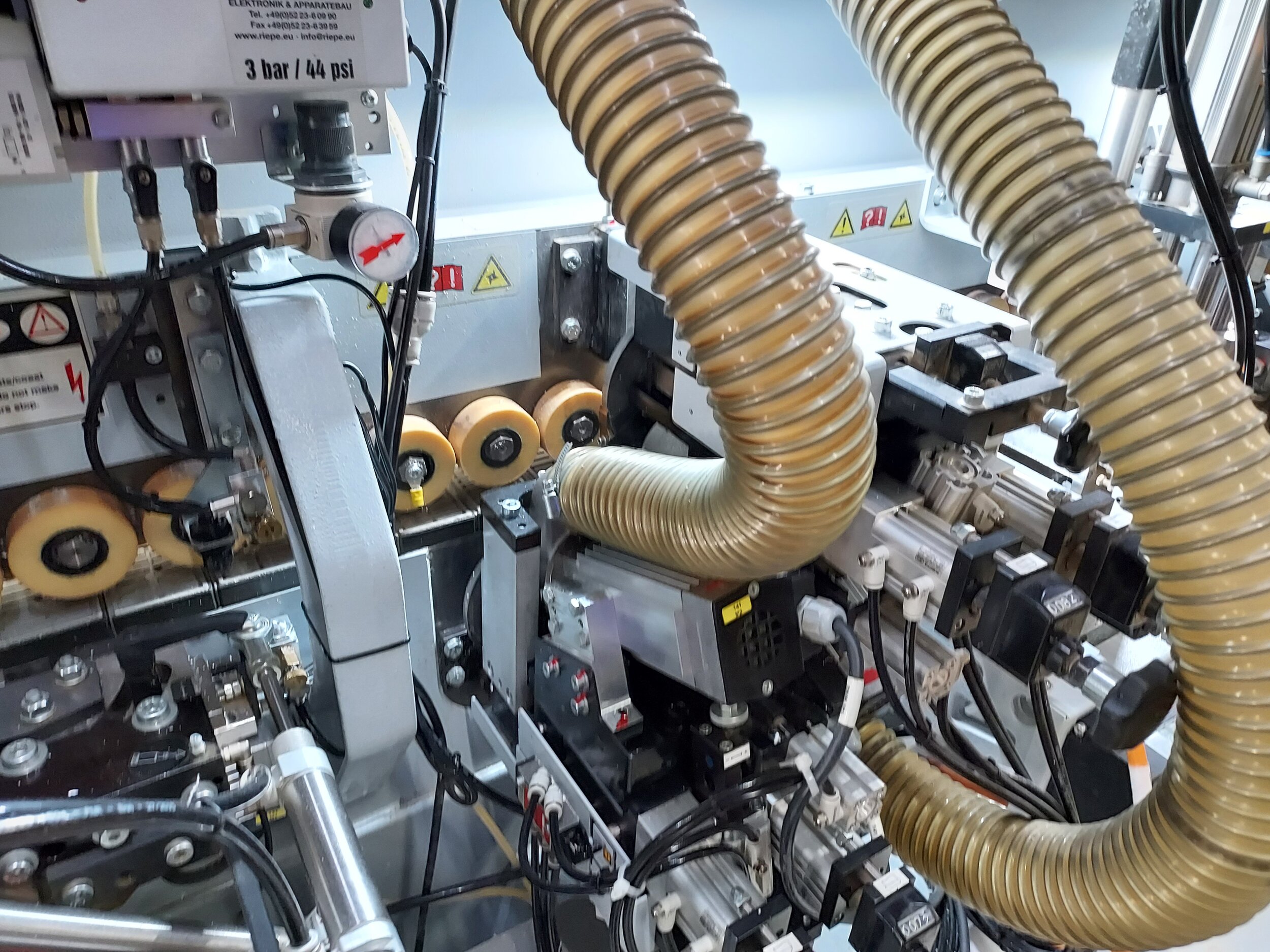

· first pressure roller driven and two (2) idle pressure rollers with 2 position auto setting system with extra-robust pressure zone to accommodate wood strips

· Double-Motor End Trimming Unit with straight and chamfer capability. Chamfer up to 15 degrees. Program-controlled indexing from straight to bevel end trimming

· Fine Trimming Unit with program-controlled pneumatic indexing, equipped with DFC cutter heads, “quick tilt” feature, and combination radius / straight carbide inserts. Nested top copy system.

· Single-Motor Contour Trimming Unit

· Quick-Change Profile Scraping Unit with pneumatic indexing and equipped with two (2) reversible profile knives to remove knife marks from thick PVC, one (1) set of tooling with nested top and bottom copy system

· Finish Scraping Unit

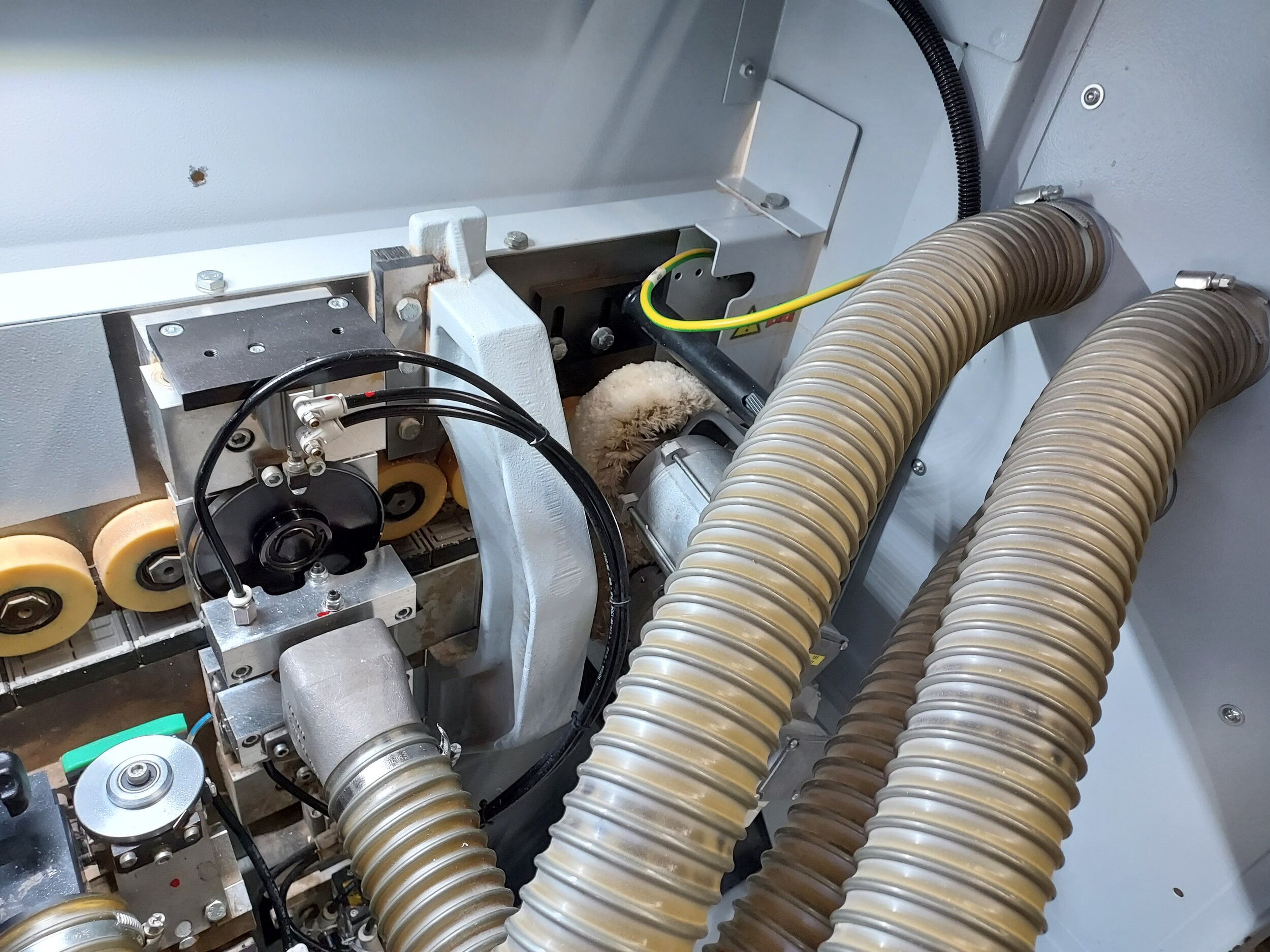

· Buffing Unit with two (2) motors, two (2) cloth buffing discs (150 x 20 mm diameter)

Technical Specifications

edgeband thickness: COILS 0.4 – 3 mm (1/64 – 1/8 in)

STRIPS 0.4 – 6 mm (1/64 – 1/4 in)

edgeband length: STRIPS 229 mm (9 in)

workpiece length: MIN 140 mm (5 1/2 in)

workpiece width: MIN 70 mm (2 3/4 in)

workpiece thickness: 8 – 60 mm (5/16 – 2 3/8 in)

feed speed: 8 m/min (26 ft/min)

pressure section: first roller driven, two (2) rollers idle

joint trimming unit (2x): 2.2 kW (3 HP) each / 12,000 rpm

end trimming unit (2x): 0.18 kW (1/4 HP) each / 12,000 rpm

fine trimming unit (2x): 0.27 kW (1/3 HP) each / 12,000 rpm

contour trimming unit (1x): 0.35 kW (1/2 HP) / 12,000 rpm

MIN workpiece length: 250 mm

total power required: 15 kW

amperage: @ 230V 42 amps

@ 460V 21 amps

machine length: 4,773 mm (15 1/2 ft)

machine width: 1,300 mm (4 1/2 ft)

working height: 950 mm (37 1/2 in)

total height (with hoods open): 2,180 mm (7 ft)

machine weight: 1,500 kg (3,300 lb)

electrical connection: 208/230/440/480V / 3-phase / 60 Hz

dust extraction: (1x) 120 mm, (3x) 80 mm, (1x) 100 mm, 2,035 CFM

compressed air: 15 CFM, 6 bar (87 PSI)

airTec compressed air: 25 CFM, 3 bar (44 PSI), 1/2” ID airline.

The return conveyor is not for sale

Machine Features:

· integrated electronic line control system for increased reliability and diagnostic assistance – no limit switches used for setting operating units

· automatic magazine for strip and coil

· large coil table (800 mm diameter) to accommodate large coils of 3 mm PVC

· feed speed: 8 m/min

· workpiece thickness: 60 mm

· workpiece pre-heating (radiant style) for achieving optimal bond quality

· Joint Trimming Unit for pre-trimming the workpiece edge prior to processing

· QA-65 N glue application system with quick purge system

· automatic temperature reduction feature lowers the glue temperature if no workpiece is run over a 15-minute span (reheating accomplished in three minutes).

· AT 10 airTec Reactivation Unit for use with laser edgebanding to provide zero glue line results. Maximum workpiece thickness is 40 mm when using airTec

· first pressure roller driven and two (2) idle pressure rollers with 2 position auto setting system with extra-robust pressure zone to accommodate wood strips

· Double-Motor End Trimming Unit with straight and chamfer capability. Chamfer up to 15 degrees. Program-controlled indexing from straight to bevel end trimming

· Fine Trimming Unit with program-controlled pneumatic indexing, equipped with DFC cutter heads, “quick tilt” feature, and combination radius / straight carbide inserts. Nested top copy system.

· Single-Motor Contour Trimming Unit

· Quick-Change Profile Scraping Unit with pneumatic indexing and equipped with two (2) reversible profile knives to remove knife marks from thick PVC, one (1) set of tooling with nested top and bottom copy system

· Finish Scraping Unit

· Buffing Unit with two (2) motors, two (2) cloth buffing discs (150 x 20 mm diameter)

Technical Specifications

edgeband thickness: COILS 0.4 – 3 mm (1/64 – 1/8 in)

STRIPS 0.4 – 6 mm (1/64 – 1/4 in)

edgeband length: STRIPS 229 mm (9 in)

workpiece length: MIN 140 mm (5 1/2 in)

workpiece width: MIN 70 mm (2 3/4 in)

workpiece thickness: 8 – 60 mm (5/16 – 2 3/8 in)

feed speed: 8 m/min (26 ft/min)

pressure section: first roller driven, two (2) rollers idle

joint trimming unit (2x): 2.2 kW (3 HP) each / 12,000 rpm

end trimming unit (2x): 0.18 kW (1/4 HP) each / 12,000 rpm

fine trimming unit (2x): 0.27 kW (1/3 HP) each / 12,000 rpm

contour trimming unit (1x): 0.35 kW (1/2 HP) / 12,000 rpm

MIN workpiece length: 250 mm

total power required: 15 kW

amperage: @ 230V 42 amps

@ 460V 21 amps

machine length: 4,773 mm (15 1/2 ft)

machine width: 1,300 mm (4 1/2 ft)

working height: 950 mm (37 1/2 in)

total height (with hoods open): 2,180 mm (7 ft)

machine weight: 1,500 kg (3,300 lb)

electrical connection: 208/230/440/480V / 3-phase / 60 Hz

dust extraction: (1x) 120 mm, (3x) 80 mm, (1x) 100 mm, 2,035 CFM

compressed air: 15 CFM, 6 bar (87 PSI)

airTec compressed air: 25 CFM, 3 bar (44 PSI), 1/2” ID airline.

The return conveyor is not for sale

Machine Features:

· integrated electronic line control system for increased reliability and diagnostic assistance – no limit switches used for setting operating units

· automatic magazine for strip and coil

· large coil table (800 mm diameter) to accommodate large coils of 3 mm PVC

· feed speed: 8 m/min

· workpiece thickness: 60 mm

· workpiece pre-heating (radiant style) for achieving optimal bond quality

· Joint Trimming Unit for pre-trimming the workpiece edge prior to processing

· QA-65 N glue application system with quick purge system

· automatic temperature reduction feature lowers the glue temperature if no workpiece is run over a 15-minute span (reheating accomplished in three minutes).

· AT 10 airTec Reactivation Unit for use with laser edgebanding to provide zero glue line results. Maximum workpiece thickness is 40 mm when using airTec

· first pressure roller driven and two (2) idle pressure rollers with 2 position auto setting system with extra-robust pressure zone to accommodate wood strips

· Double-Motor End Trimming Unit with straight and chamfer capability. Chamfer up to 15 degrees. Program-controlled indexing from straight to bevel end trimming

· Fine Trimming Unit with program-controlled pneumatic indexing, equipped with DFC cutter heads, “quick tilt” feature, and combination radius / straight carbide inserts. Nested top copy system.

· Single-Motor Contour Trimming Unit

· Quick-Change Profile Scraping Unit with pneumatic indexing and equipped with two (2) reversible profile knives to remove knife marks from thick PVC, one (1) set of tooling with nested top and bottom copy system

· Finish Scraping Unit

· Buffing Unit with two (2) motors, two (2) cloth buffing discs (150 x 20 mm diameter)

Technical Specifications

edgeband thickness: COILS 0.4 – 3 mm (1/64 – 1/8 in)

STRIPS 0.4 – 6 mm (1/64 – 1/4 in)

edgeband length: STRIPS 229 mm (9 in)

workpiece length: MIN 140 mm (5 1/2 in)

workpiece width: MIN 70 mm (2 3/4 in)

workpiece thickness: 8 – 60 mm (5/16 – 2 3/8 in)

feed speed: 8 m/min (26 ft/min)

pressure section: first roller driven, two (2) rollers idle

joint trimming unit (2x): 2.2 kW (3 HP) each / 12,000 rpm

end trimming unit (2x): 0.18 kW (1/4 HP) each / 12,000 rpm

fine trimming unit (2x): 0.27 kW (1/3 HP) each / 12,000 rpm

contour trimming unit (1x): 0.35 kW (1/2 HP) / 12,000 rpm

MIN workpiece length: 250 mm

total power required: 15 kW

amperage: @ 230V 42 amps

@ 460V 21 amps

machine length: 4,773 mm (15 1/2 ft)

machine width: 1,300 mm (4 1/2 ft)

working height: 950 mm (37 1/2 in)

total height (with hoods open): 2,180 mm (7 ft)

machine weight: 1,500 kg (3,300 lb)

electrical connection: 208/230/440/480V / 3-phase / 60 Hz

dust extraction: (1x) 120 mm, (3x) 80 mm, (1x) 100 mm, 2,035 CFM

compressed air: 15 CFM, 6 bar (87 PSI)

airTec compressed air: 25 CFM, 3 bar (44 PSI), 1/2” ID airline.

The return conveyor is not for sale